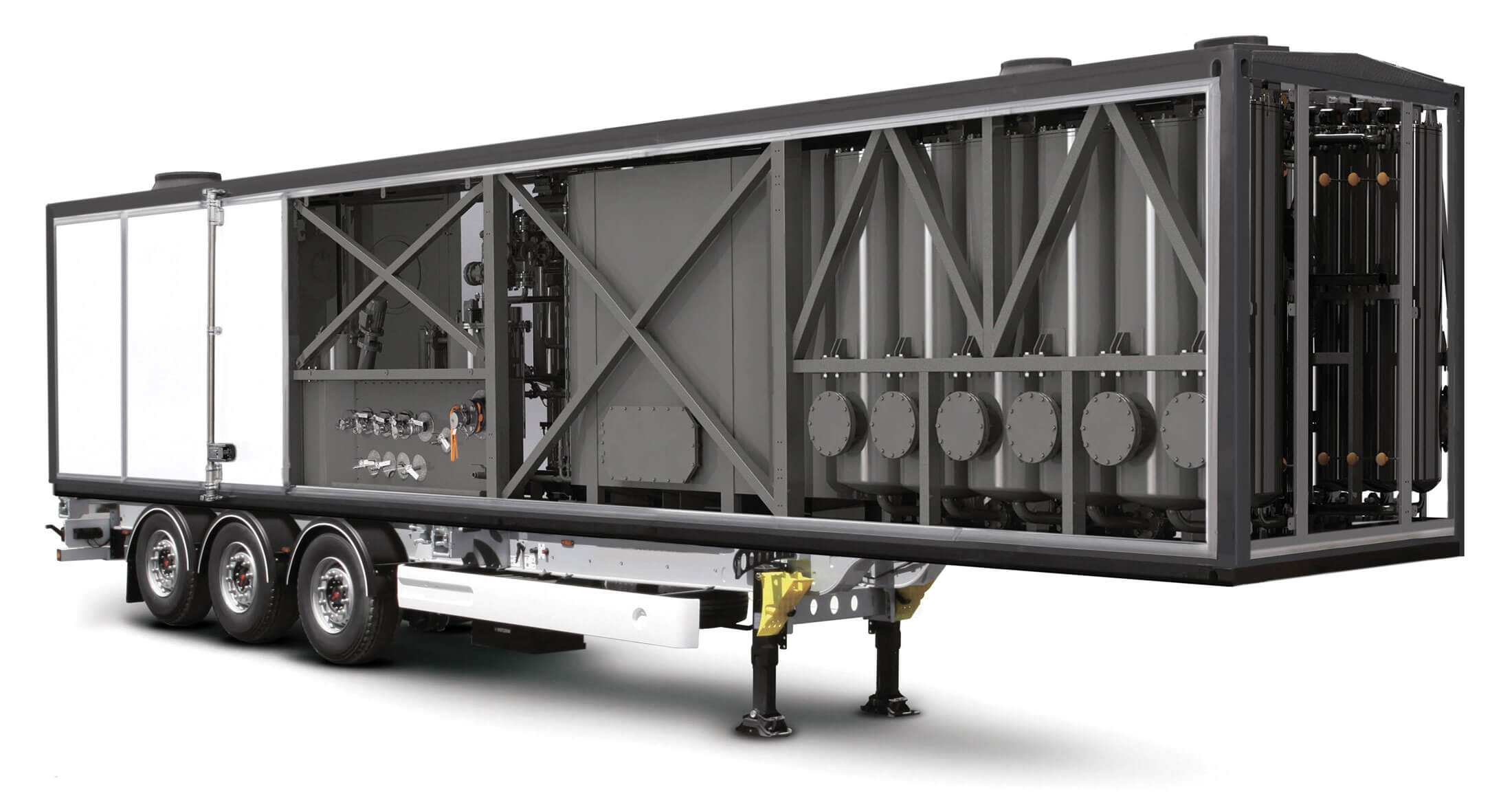

CMM-12R Oil Regeneration Systems

The GlobeCore regeneration process restores used oils to new like condition. This process makes it possible to fill transformers with oil that would previously have required disposal. The oil in the transformer can be used without replacement for the entire service life of the transformer.

The GlobeCore CMM-R systems are designed to extend transformer service life by restoring the dielectric strength and chemical composition of dielectric insulating oil.

In the process of oil regeneration, oil degradation products and acidic compounds are removed, the oil becomes clear, oxidation resistance is improved, while gas solubility is reduced.

| № |

Parameter |

Value |

| 1 | Capacity, l/h (gpm) |

1000 (4,4) |

| 2 | Oil losses during operation, % |

2-25 |

| 3 | Maximum allowed oil temperature, оС (оF) |

90 (194) |

| 4 | Outlet pressure, bar (psi) |

2,5 (36,25) |

| 5 | Oil heater power, kW |

24 |

| 6 | Rated vacuum suction speed, l/h (gpm) |

280 000 (1232,8) |

| 7 | Fuller’s Earth mass, kg (lbs) |

1600 (3527,4) |

| 8 | Electrical power parameters | |

| Voltage, V |

Customizable |

|

| Frequency, Hz | ||

| 9 | Coarse filtration fineness (mesh filter), µm |

100 |

| 10 | Pre-filtration fineness, µm |

25 |

| 11 | Fine filtration fineness, µm |

5 |

| 12 | Dimensions, mm (in) | |

| Length |

5500(217) |

|

| Width |

2320 (91) |

|

| Height |

2450 (96) |

|

| 13 | Weight, kg (lbs) |

6000 (13227) |

Regeneration of the oil in a transformer restores used oil to new like condition:

| Parameter | Before processing | After processing |

| Moisture content by weight,g/t (ppm) as per IEC 733; ASTM D-1533 | 43 | 5 |

| ISO 4406 industrial purity class | -/18/16 | -/14/12 |

| Volumetric gas content % I.A.W.IEC 60599; ASTM D-3612 | – | 0.1 |

| Acid number, mg KOH/g I.A.W IEC 296; ASTM D-664 | 0.2 | 0.01 |

| Corrosive sulfur I.A.W.*IEC 5662; ASTM D-1275 | present | absent |

| Dielectric strength, kV I.A.W. IEC 156; ASTM D-18116 | 30 | 70 |

| Interfacial tension, N/m, at 25ºС I.A.W. IEC 6295; ASTM D-664 | – | 45 |

| Dissipation factor at 90ºС I.A.W.IEC 247; ASTM D-924 | 0.095 | 0.001 |

| Oxidation stability I.A.W. IEC 74; 164 hours | – | restored |

(*I.A.W. In Accordance With)

GlobeCore manufactures oil regeneration systems for both transformer manufacturers and for transformer service providers.

GlobeCore units are loaded with a sorbent that captures all oil decomposition products.

GlobeCore regeneration systems can use the same sorbent for up to 3 years before the first replacement. No more need for consumables and costly labor related to replacement of exhausted sorbent on the job site.

Regeneration systems can be combined with degassing units or can be purchased as stand-alone systems.

GlobeCore regeneration systems can be used in combination with your existing degassing or drying unit.

Each GlobeCore unit can be customized and includes a number of options:

- An extra vacuum pump assembly for transformer vacuuming

- Mounted on a trailer or a semi-trailer

- Inlet and/or outlet moisture meters for the oil stream

- Remote control and process monitoring via smartphone or PC

- Climate Controlled Operator work room.